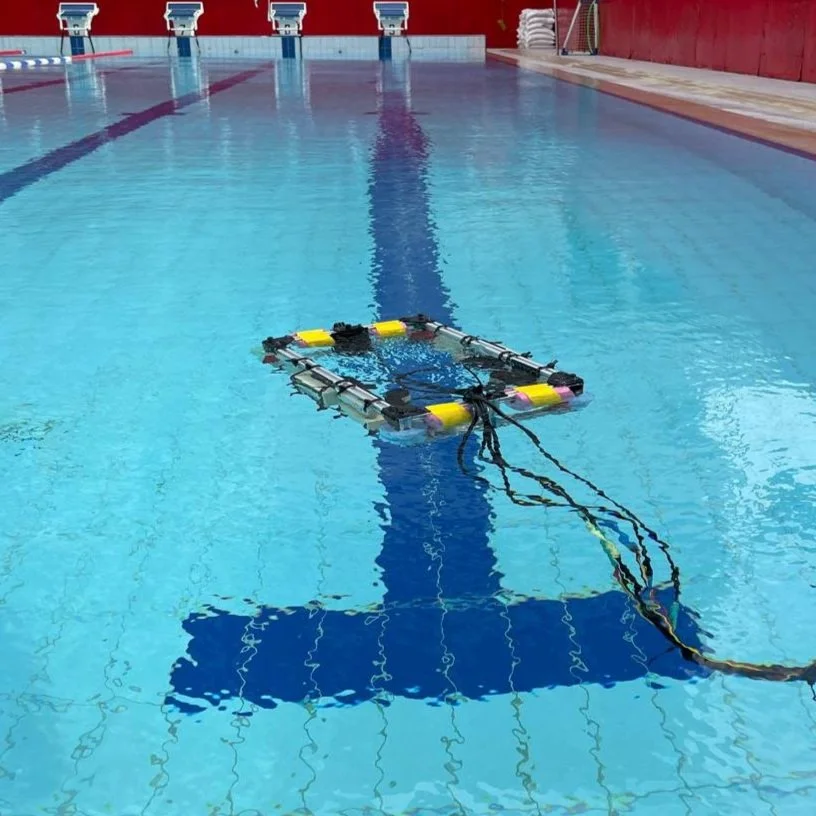

Designing an underwater ROV for the MATE competition

Served as mechanical design and fabrication lead for my team

Trained new members to use shop tools

Guided design process

Taught an optional course in computer aided design (CAD) and 3D modelling

Competed in the MATE worlds competition

What is MATE?

The MATE ROV Competition simulates using under water robotics (ROVs) to solve real-world problems. Teams are required to learn and employ a variety of scientific, engineering, and technical skills. Each team is required to complete a series of missions based on scenarios from the real world, such as seeding coral or laying underwater cables.

Learning to collaborate and lead

My first time being in a leadership position taught me a lot of new skills

Developed effective leadership strategies and team management

Learned effective communication methods for larger teams

Acquired effective teaching skills

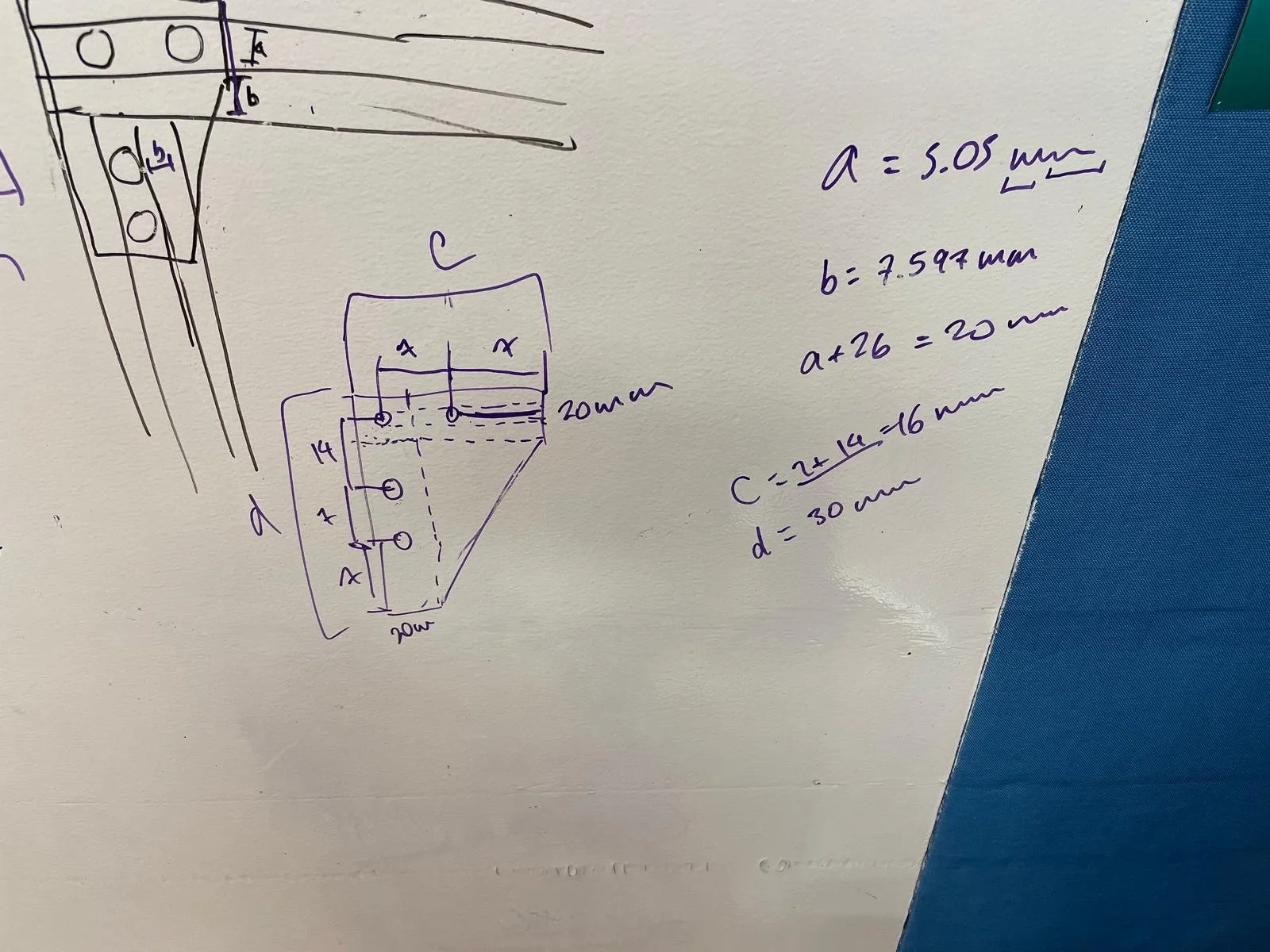

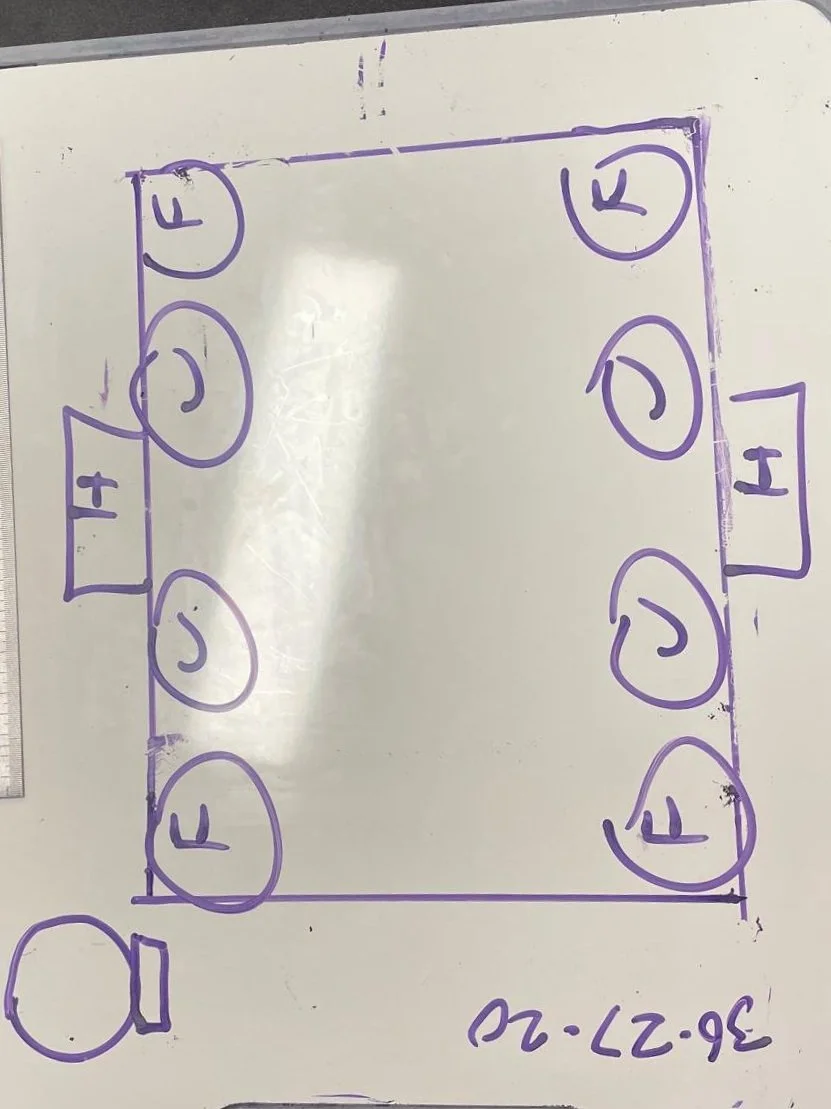

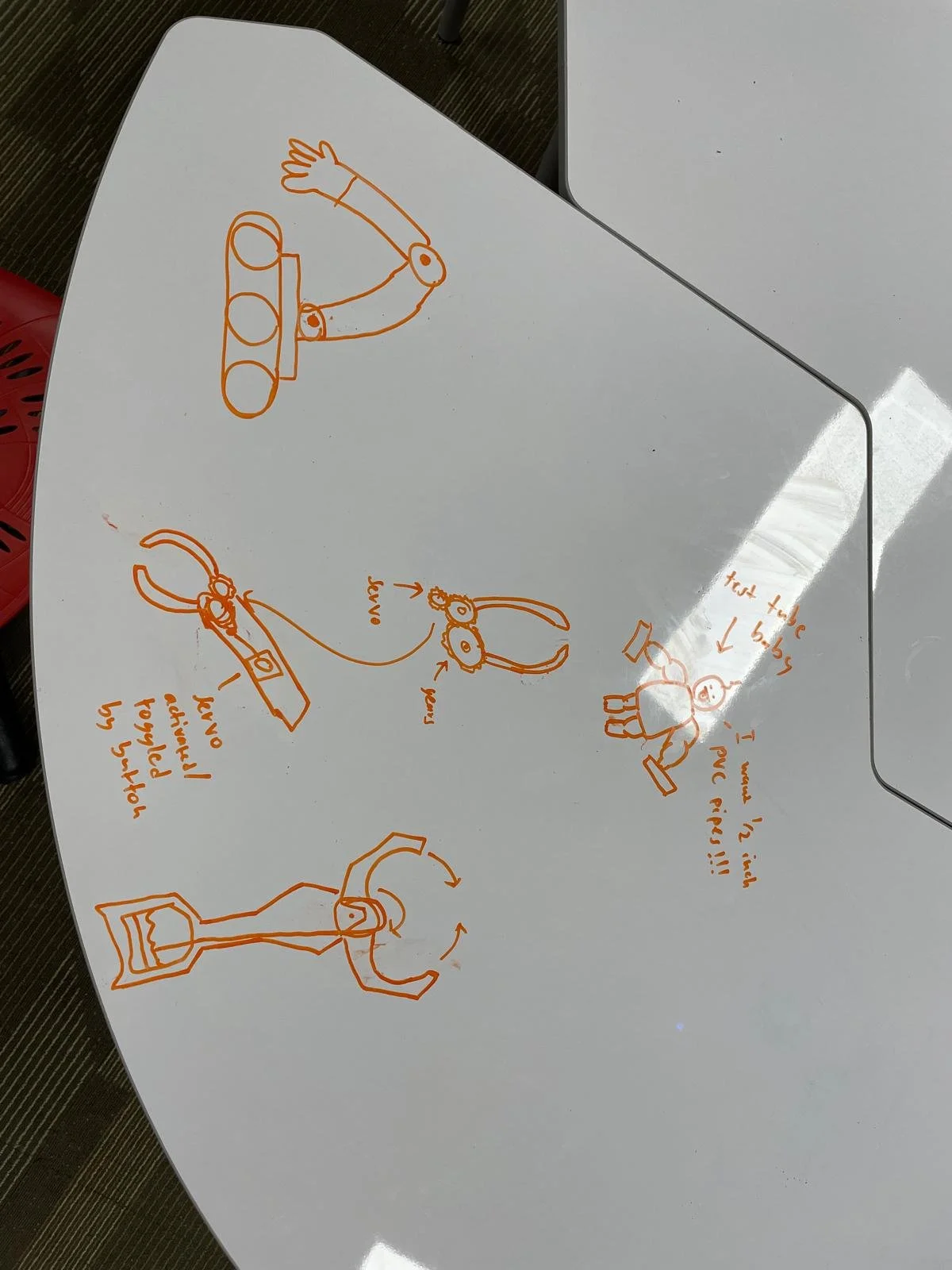

Problem Definition & Brainstorming

Reading through the competition rule book, we outlined the specific capabilities required of our ROV for each task. Allowing us to brainstorm possible designs / solutions.

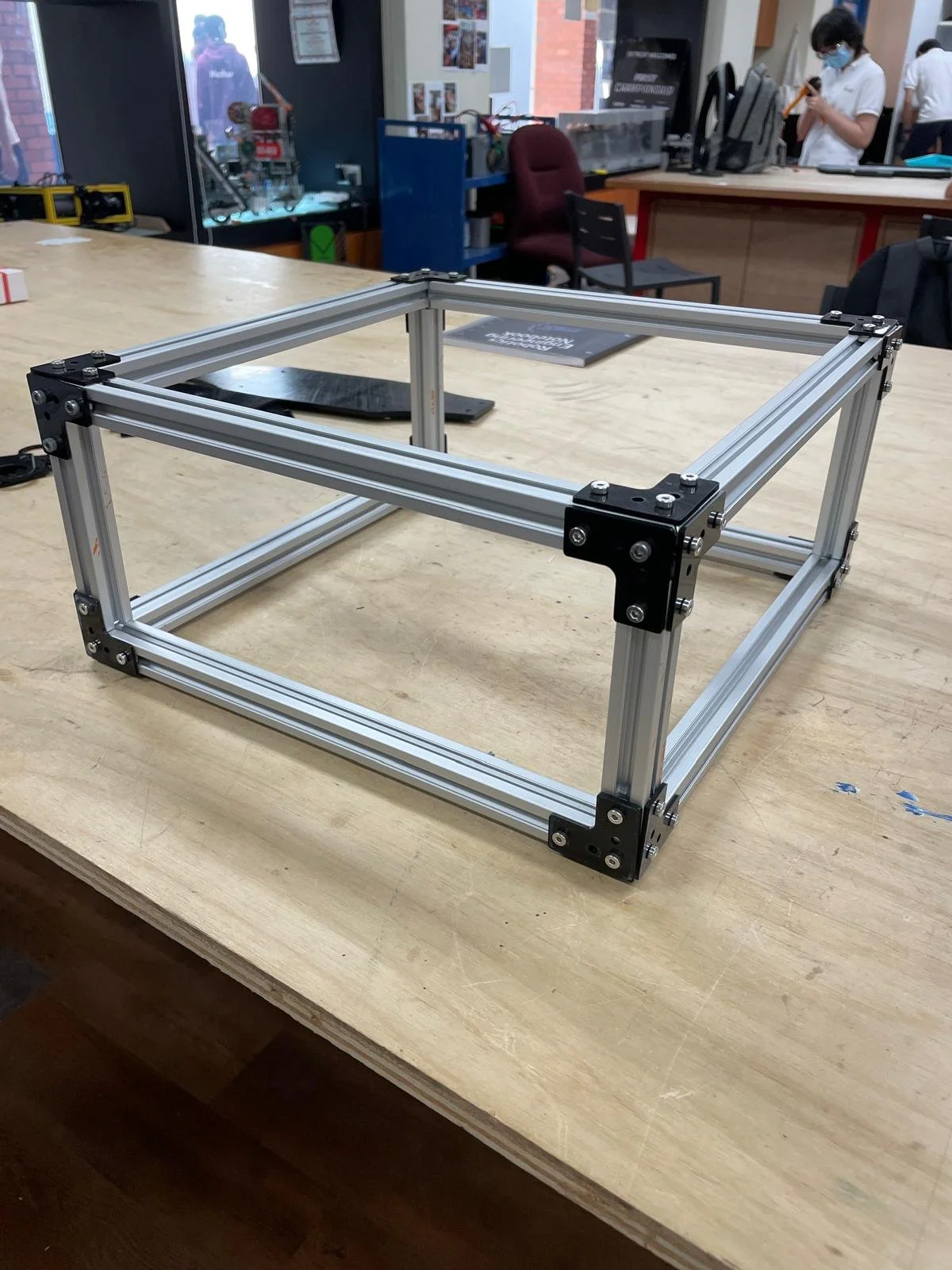

Creating & Testing Models

Helped members fabricate the frame

Worked with new materials

Lead testing for prototypes

Skills Developed

-

As the mechanical lead of my robotics team, I learned valuable team management skills by organizing our group into specialized subteams, each focusing on a critical aspect of our design. I divided responsibilities among teams working on the frame, robotic arm, buoyancy, and hardware mounting, ensuring that each subteam had clear objectives and deadlines. This structure not only streamlined our workflow but also taught me how to coordinate efforts, balance workloads, and adapt plans to keep the project on track.

-

Leading my robotics team strengthened my teaching skills as I hosted lessons on computer-aided design, 3D modeling, and shop tool safety. Explaining complex topics in clear steps helped teammates learn effectively while reinforcing my ability to adapt to different skill levels.

-

Leading my robotics team taught me how to innovate by improving past designs. I experimented with switching the frame from aluminum to carbon fiber rods for a lighter, more durable structure. I also redesigned the mechanical arm for greater articulation and upgraded the maneuvering system to enable full six-axis motion, enhancing the robot’s agility and precision.